Foam Evaluation and Test Equipment

Modified Ross-Miles Foam Cell

Our made-in-house Ross-Miles Foam Cell is the perfect piece of equipment for field work and preliminary screening of defoamer products in low viscosity mediums. Surfactant solution is filled into the unit and a pre-set temperature heats and holds the liquor in uniform conditions. A varibale flow meter can be turned on to begin cycling the liquor around the unit, causing foam generation and a rising foam layer in the clear glass column. Defoamer is added to the top of the glass column when the foam is near the top and the technician measure foam height over time as the defoamer eliminates the foam.

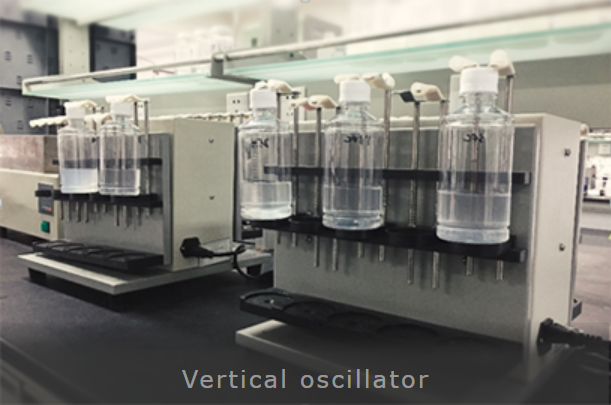

Vertical Oscillating Shake test

The vertical oscillating shake test is a great method to determine comparative foam control properties in multiple samples at once. Surfactant solution with defoamer is added to each jar and then shaken repeatedly, causing foam to occur. Foam control is measured by visual inspection and defoaming effect is measured after shaking ceases. This machine removes the human error of a shake test.

Automatic Coating Draw Down

Bench work performed with coating samples is essential for ensuring defoamer compatibility with the customers coating. Different formulations, demands, and ingredients are popular all over the world, eliminating the possibility of “one size fits all” defoamer products. Controlling foam during mixing is essential for a formulator, but examining surface properties after the coating has been applied is of equal or greater importance. SIXIN has invested in several pieces of equipment to standardize our coating draw downs so that comparing surface properties of multiple samples is uniform, accurate, and repeatable.

The test methods and equipment listed above are just a small feature of what we have available in our lab. If you are a current or prospecting customer, please contact SIXIN to learn more information or schedule a tour of our facility!